<< Go Back up to Theatre Research

The safety curtain (predominantly UK) or fire curtain (predominantly US) separates the stage from the auditorium with a fireproof and smokeproof barrier, and is intended to slow or stop a fire which has started in one of the two areas from reaching the other. Safety/Fire curtains are fitted to the rear of the proscenium arch, usually within tightly-fitting channels and with a padded bottom all to help ensure a tight fit to minimize air/smoke movement.

In some jurisdictions safety/fire curtains were originally created from sheet metal and hence called iron curtains, or “iron” for short.

The Royal Lyceum Theatre Edinburgh (opened in 1883) was reported in the Scottish media of the time to have been fitted with the first iron safety curtain in the UK, however research shows the third Theatre Royal, Drury Lane in London was fitted with an iron safety curtain in 1794.

Despite safety/fire curtains being fitted in some theatres, it was not until after the tragic fire of 1887 at the Royal Theatre, Exeter (UK), which claimed nearly two hundred lives and could have been prevented by the presence of a fire/safety curtain, that they started to become the norm in theatres across the UK and US.

In the early 20th century safety/fire curtains were commonly metal frames skinned with asbestos fiber-based material due to its fire-resistant properties. As the health hazards surrounding asbestos fibers have become better understood during the latter part of the 20th century, these potentially life-saving fire curtains have become something of a problem for theatres to deal with. That said – and approaches to this vary per country – it is generally accepted that an asbestos curtain which is painted, and has no damage to the paint, retains the asbestos fibers behind the paint layer(s) and is considered safe to use.

In some jurisdictions, for example the City of Los Angeles, in some cases safety/fire curtains are not a legal requirement – but if they have been installed they must be operative.

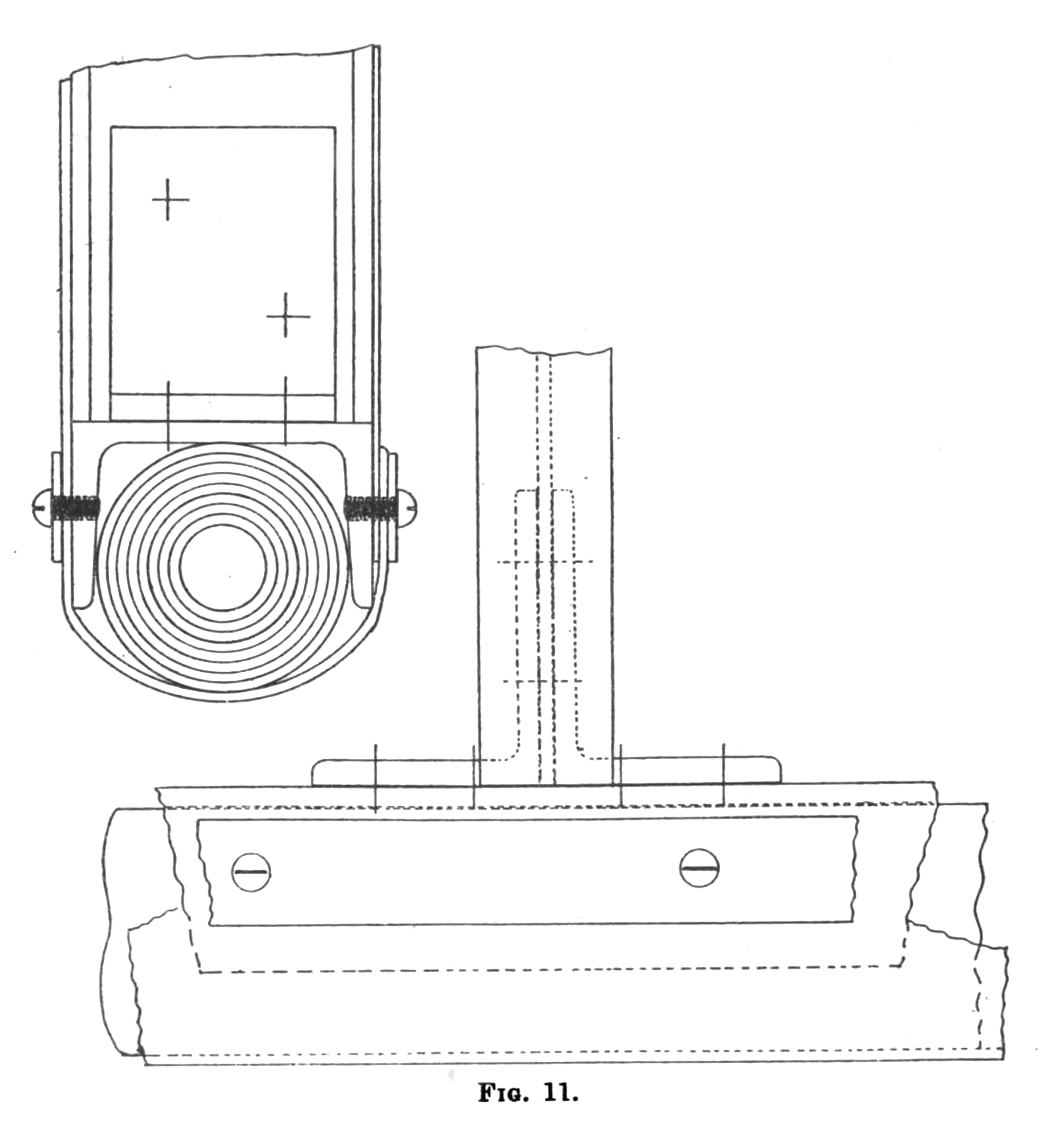

Some jurisdictions have minimum speed requirements for the full operation of the safety/fire curtain to complete. Fast automatic operation of safety/fire curtains may be achieved in different ways which may include “dumping” of some of the counter-balancing weights to allow the curtain to fall quickly using gravity. As fast descending safety/fire curtains could be very hazardous around people, most installations incorporate a mechanism to slow the descent of the curtain as it reaches “people height” and for the remainder of its descent to the stage floor. Such mechanisms include the dashpot, a mechanical device which resists motion via viscous friction.

Most modern safety/fire curtain installations have both automatic and manual modes of operation. Automatic operation is commonly by a release lever or rope to be cut by a human operator, the automatic part of the system being the lowering of the safety curtain in a safe and controlled manner. Fully automatic systems may be connected to the building’s fire detections system. Significant intervention may be required to reset the safety/fire curtain after automatic deployment. Manual deployment is similar to operating any other counterweight flown piece on the theatre’s flying system, although more recent regulations in many jurisdictions require motor operation for new safety/fire curtain installations.

Some installations include a “drencher” (also called a deluge or sprinkler), essentially a water pipe with holes along its length, located above the safety/fire curtain and running its entire width. When the curtain is deployed in a non-manual situation, water is pumped through the drencher system to dampen the curtain and prolong the effectiveness of its fireproof properties.

You can read more about different types of curtains to suit different types of theatre here  on the iWEISS website.

on the iWEISS website.

It is common belief in the UK that safety/fire curtains must be demonstrated to the audience at every performance to prove that they work, something which is often done at the interval (intermission in the US) and is commonly known as “bouncing the iron”. This is not true; rather the regulations are made at local authority level. When the Home Office pushed recommendations for local authorities to follow in 1935, most authorities followed suit, and that is why most local authorities still follow the same rules today and make it appear that there is a UK-wide ruling on the matter.

In 1935, the UK Her Majesty’s Stationery Office (HMSO) published a book aimed at providing UK-wide theatres guidance on theatre safety. At the time, and still to this day, regulations around fire/safety curtains are the responsibility of the local fire authority. This is why you might see a production in London’s West End where the safety curtain is never demonstrated to the audience. The Home Office got as close as they possibly could to laying down the rules, and many local authorities adopted them. Read on for the detail from the 1935 publication.

Further Reading:

by K&D Fire & Smoke Protection Systems

by K&D Fire & Smoke Protection Systems from the Fire Safety Advice Centre

from the Fire Safety Advice CentreThe Manual of Safety Requirements in Theatres and Other Places of Public Entertainment was first published by Her Majesty’s Stationery Office (HMSO) in 1935 and reprinted in 1949. An online version is available on the HathiTrust website  (availability may be restricted by country in avoidance of potential copyright reasons).

(availability may be restricted by country in avoidance of potential copyright reasons).

There is no doubt that where a stage and scenery is employed the most dangerous area will be on or about the stage and every precaution must be taken to provide a measure of fire separation between the audience and the stage which will function till clearance can be effected, and so to arrange the ventilation as to give prompt and certain vent to smoke, flame, and hot gases from a fire arising on or about the stage otherwise than through the proscenium opening. Fire separation can be provided by means of a fire-resisting proscenium wall and fire-resisting curtains with drenchers over; ventilation by roof vents which will ensure that there is a ready means of escape for fire, smoke and hot gases through the stage roof. The Ring Theatre fire in Vienna in 1881 led to experiments being carried out by the Austrian Society of Engineers in 1885 and by the Austrian Government in 1895. A model approximating one-third linear dimensions (or 1/27th cubical content) was used and some very remarkable results were obtained. In one experiment the roof vents were tightly closed, and within 20 seconds of the scenery on the stage being well alight pressure rose to 5 inches of water and the curtain was blown into the auditorium. This explained why the gas lights in the Ring Theatre had been extinguished, because pressure of gas at the jets would never be more than 3 lbs. With the roof vents open, no pressure was produced in the auditorium and the draught from auditorium to stage was sufficient to bulge the curtain towards the stage.

It will be seen from definition (10) on page 6 that the term “scenery” does not include metal or asbestos scenery or hangings consisting of certain materials of the weights therein mentioned.

Where no scenery other than the above is used on the stage, it is not suggested that the provisions of this Part of the Manual should be applied. Where any other form of scenery is used, however, this Part should be rigidly applied.

The provision of at least a fire-resisting wall, some form of roof vent and a curtain with fire-resistance equivalent to that of a heavy wool curtain, with a system of drenchers to keep it wet for a short period, is the minimum compatible with safety and it is strongly recommended that these safeguards be provided in all buildings seating over 400 persons even if only occasionally used. This will probably involve structural alterations which may be somewhat costly, and it is suggested that notice be given to owners of such buildings that alterations to enable the building to comply with these requirements should be completed, within a period of, say, one year in the case of places regularly used and two years in places occasionally used. The method suggested for determining whether a particular place is used “regularly” or “occasionally” for purposes of this Manual is set out in definition (4) on page 6 and, for purposes of the application of this Part of the Manual, it is felt that account should be taken only of those performances which consist of stage plays and entertainments of that nature. In addition, it will be observed from the various tables of requirements which follow in this Part that exemption from the provisions considered therein is suggested for places used “occasionally and exceptionally only on not more than twelve days in any one year”.

Until such safeguards as are here suggested are provided, there is much to recommend the procedure adopted in some cities where a trained fire brigade exists. In those cities, a member of the fire brigade is on duty on the stage during all performances. The fireman’s time is paid for by the owner or licensee of the premises. The presence of a trained man will ensure that fire appliances are got to work promptly and efficiently and, in the absence of the safeguards provided by a reliable cut off between the stage and the auditorium, it is essential that the fire should be held in its earlier stages. Appliances available for use by this man should include at least a Mark 3 hand-pump but, if the requirements of this Manual as regards fire appliances are adhered to, such an appliance will be available wherever a stage and scenery is employed in a building seating over 400 persons.

In addition to the stage itself, there are other places, such as scene docks, workshops and stores, in which material of a combustible nature is present and which therefore constitute definite risks. These places are included in the expression “the stage risk” and steps should be taken by way of adequate fire separation, sprinkler protection, etc., to isolate from the rest of the stage risk any outbreak of fire which may occur in these parts of the building. It is realised that in many old buildings the provision of fire- resisting walls and so on for these portions of the building may be impracticable, but this provision should certainly be made in new buildings.

In new buildings and in buildings with a stage area exceeding 600 square feet, the proscenium wall should be of the highest possible class; for smaller stages and buildings occasionally used, something simpler and less expensive might be allowed, and it is suggested that three different classes of proscenium wall be provided for different types of building and user, as follows:—

[Missing Page]

At the Iroquois Theatre, Chicago, at Edinburgh, and at Madrid, the curtain failed to come down all the way and was of little value. Reference is made to the cause of failure in a later paragraph.

It is advised that curtains of varying degrees of fire-resistance be provided for different classes of buildings, as set out in the table below.

A general Requirement is recommended in the following terms:–

| Class of building and user. | Grade of curtain required. |

|---|---|

| 1. In new buildings seating over 400 persons. | A = Rigid one-piece curtain complying with Requirements 59 to 65. |

| 2. Existing buildings regularly used with stage area over 600 square feet. | B = Rigid two-piece curtain complying with Requirements 59 to 65. |

| 3. Existing buildings regularly used with stage area less than 600 square feet. | C = Rigid three-piece curtain complying with Requirements 59 to 65. |

| 4. Existing buildings occasionally used seating over 1,000 persons. | D = Roller asbestos curtain complying with Requirements 60 to 65. |

| 5. Existing buildings occasionally used seating over 700 but not more than 1,000 persons. | E = Roller or festooning asbestos curtain complying with Requirements 60 to 65. |

| 6. Existing buildings occasionally used seating over 400 but not more than 700 persons. | F=Heavy wool curtain complying with the specification on page 50 and having at least 18 inches overlap if parted in centre and 18 inches overlap over proscenium arch. |

The following constructional Requirements should be applied in respect of rigid safety curtains:—

In addition to the foregoing, there are certain other Requirements which apply to safety curtains generally whether or not they are of the rigid type :—

The Manual of safety requirements in theatres and other places of public entertainment’s Requirement and Condition suggested for adoption No. 66 is the rule which was, and still is, largely adopted by all local authorities throughout the UK, and from which the general understanding that this is a UK-wide rule comes from.

In a newspaper article recounting the tale of the gruesome fire  which claimed the life of The Great Lafayette on the stage of what is now the Edinburgh Festival Theatre, it was stated that as a result of the tragedy “The Lafayette Bill brought in the lowering and raising of the safety curtain at every performance to ensure it is fully working and will do its job in the event of an incident”. Thus far no evidence has been offered to support this claim, and it is not supported at a UK national level by Hansard, the official report of all Parliamentary debates. It may be that the Lafayette Bill was local to Edinburgh.

which claimed the life of The Great Lafayette on the stage of what is now the Edinburgh Festival Theatre, it was stated that as a result of the tragedy “The Lafayette Bill brought in the lowering and raising of the safety curtain at every performance to ensure it is fully working and will do its job in the event of an incident”. Thus far no evidence has been offered to support this claim, and it is not supported at a UK national level by Hansard, the official report of all Parliamentary debates. It may be that the Lafayette Bill was local to Edinburgh.

Failure of the fire-resisting curtain occurred at Edinburgh, where there was some hesitation in lowering the curtain because a spotlight and its operator had not moved out of the way. An ordinary drop curtain was lowered, but this was carried inwards by the draught from the auditorium to the stage and jambed the safety curtain by blocking the guides. At the Iroquois Theatre a swinging spot-light bracket stopped the descent of the curtain. At Madrid ambiguous orders were given and again the subsequent lowering of the fire-resisting curtain was impeded by a drop curtain.

At the Palace Theatre, New York, in 1932, before the fire-proof curtain could be lowered or the automatic roof vents had opened, a draught from the stage towards the auditorium caused the fire to pass below the curtain, and this set fire to a cloth valance curtain on the auditorium side of the proscenium opening. Although the fire-resisting curtain, roof vents, drenchers and sprinklers all functioned perfectly and the fire was extinguished with very little damage, the burning valance curtain caused a stampede towards the exits and, though these were ample, several people were injured.

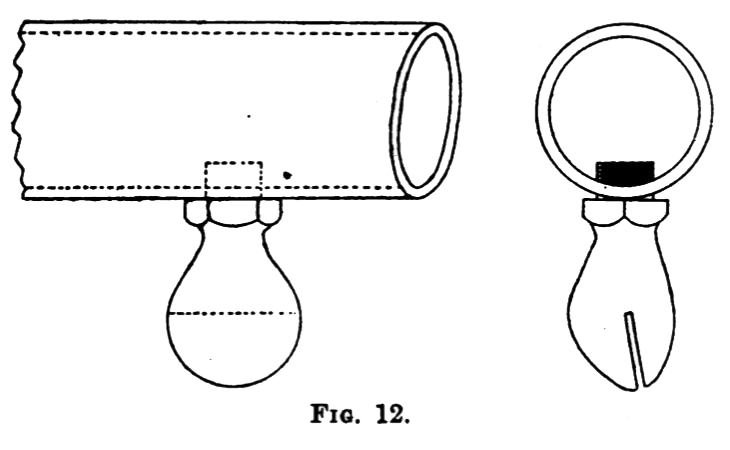

The function of these drenchers is two-fold. In curtains of the rigid type they will prevent distortion of the metal framing of the curtain and also serve to keep the asbestos damp. In the non-rigid types of curtain they will keep the asbestos or wool thoroughly damp, for a period at any rate, and this will increase the weight of the curtain and make it less liable to belly out in one direction or the other. A drencher head is shown in Figure 12.

| Class of building and user. | Number and arrangement of Release positions. |

|---|---|

| New buildings seating over 400 persons Existing buildings regularly used and seating over 400 persons. Existing buildings occasionally used and seating over 1,000 persons. |

A = Two release positions, one at working side stage level and the other near the principal stage exit or stage door-keeper’s office. Where staff are not usually present on the stage, release position may be on auditorium side of proscenium arch instead of working side stage level. |

| Existing buildings occasionally used and seating over 400 but not more than 1,000 persons. | B = One release position working side stage level. Where staff are not usually present on the stage, release position may be on auditorium side of proscenium arch instead of working side stage level. |

The importance of a stage roof vent for safeguarding the audience cannot be over emphasised; the Austrian experiments proved this conclusively. At Exeter, where there was no roof vent, persons in the gallery were quickly stifled and lost their lives. Comparison of two similar fires is interesting in this respect. At the Iroquois Theatre, Chicago, the roof vents were installed but work on them was not complete and they were boarded up; there was also an exhaust fan working behind the gallery seating. At Edinburgh very light roof construction and light glazing acted as a roof vent and gave passage to the fire almost at once. In both cases there was an intense fire on the stage and the fire-resisting curtain had failed to come down all the way. At Chicago many of those in the gallery were killed before they even left their seats, while at Edinburgh conditions in the auditorium were never dangerous and hardly even unpleasant for at least four minutes.

| Class of building and user. | Type of vent required. |

|---|---|

| New buildings seating over 400 persons. | A = of the roof type, see Figure 13 (i.e., windows in stage wall are not adequate). To have an area equal to one-sixth of the stage area. |

| Existing buildings regularly used with stage area over 600 square feet. | B = Of the roof type, see Figure 13. TO have an area equal to one-eighth of the stage area. |

| Existing buildings regularly used with stage area under 600 square feet. Existing buildings occasionally used seating over 1,000 persons. Existing buildings occasionally used seating over 700 but not more than 1,000 persons. |

C = Side lights (e.g., windows in the stage wall) permitted, see Figure 14; they must be bottom- or centre-hung and have an area equal to one-eighth that of the stage. |

| Existing buildings occasionally used seating over 400 but not more than 700 persons. | D = Sidelights permitted, see Figure 14. Area not less than one-tenth of stage area. |

Tests carried out in the U.S.A. proved that any wire netting below roof vents is soon choked up by pieces of light material carried by the up-current of air, and this might restrict the upward passage of fire, smoke and hot gases.

Photographs copyright © 2002-2024 Mike Hume / Historic Theatre Photos unless otherwise noted.

Text copyright © 2017-2024 Mike Hume / Historic Theatre Photos.

For photograph licensing and/or re-use contact me here  .

.

| Follow Mike Hume’s Historic Theatre Photography: |  |

|